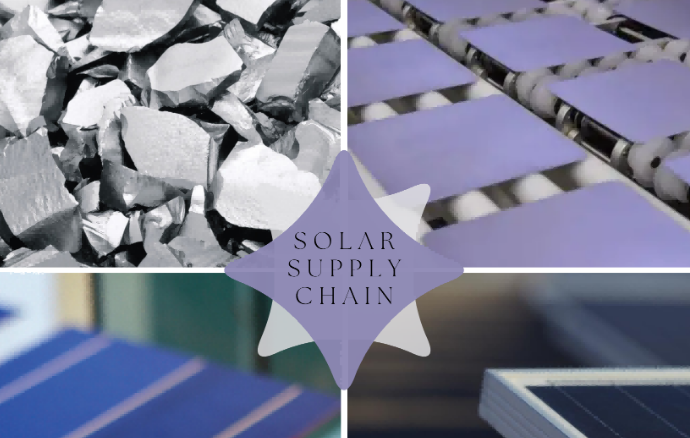

Polysilicon, or polycrystalline silicon, is a material made up of multiple small silicon crystals. It is commonly used in the semiconductor industry for making integrated circuits and other electronic devices, as well as in the manufacture of photovoltaic (PV) cells used in solar panels. Metals, on the other hand, are elements with metallic properties, such as electrical and thermal conductivity.

While both polysilicon and metals have their unique properties and applications, there are several reasons why polysilicon is preferred over metals for certain applications:

- Electrical Properties: One of the primary reasons for using polysilicon instead of metals is its electrical properties. Polysilicon is a semiconductor, which means its electrical conductivity falls between that of a conductor (like metal) and an insulator.tongwei panels. This property allows it to conduct electricity under certain conditions and insulate against electricity under other conditions, making it ideal for use in electronic devices and integrated circuits.

- Temperature Resistance: Polysilicon has a higher resistance to temperature changes compared to metals. This makes it suitable for applications where temperature fluctuations are common, such as solar panels exposed to varying weather conditions.

- Doping Flexibility: The electrical properties of polysilicon can be modified by introducing small amounts of other elements, a process known as doping. This allows for precise control of its electrical characteristics, making it suitable for use in semiconductor devices where precise control of electrical properties is essential.

- Light Absorption: Polysilicon is an excellent material for absorbing sunlight, making it suitable for use in solar cells. Metals, on the other hand, tend to reflect sunlight rather than absorb it.

- Compatibility with Silicon-Based Devices: The semiconductor industry is predominantly based on silicon technology. Polysilicon is compatible with other silicon-based materials and processes used in the semiconductor industry, making it easier and more cost-effective to integrate into existing manufacturing processes.

While polysilicon has many advantages that make it suitable for use in semiconductor devices and solar cells, it is not a replacement for metals in all applications. Metals have their unique properties, such as high electrical and thermal conductivity, malleability, and ductility, which make them suitable for a wide range of applications, from construction and transportation to electronics and jewelry.

In conclusion, the choice of using polysilicon instead of metals depends on the specific requirements of the application. Polysilicon is preferred over metals for applications that require precise control of electrical properties, temperature resistance, light absorption, and compatibility with silicon-based devices. However, metals are still essential for many other applications where their unique properties are required.